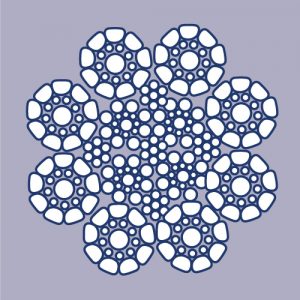

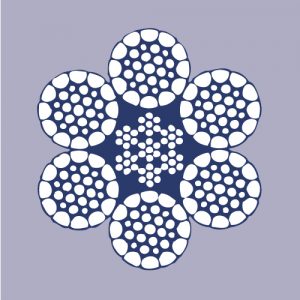

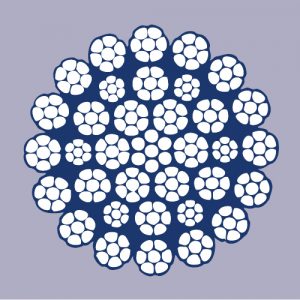

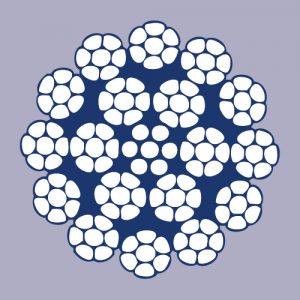

Compacted Hi Spec

We stock a variety of Compacted Hi Spec wire rope.

Compacted hi spec wire ropes offers superior lifting capacity and strength, as well as providing additional protection to the inner core on exterior applications.

Showing all 4 results